Introduction:

Wessex Tubas are known for their superior control and intonation, making them popular among tuba players. However, proper maintenance is essential to ensure optimal performance and longevity of your instrument. This guide will provide you with tips on how to maintain your Wessex Tubas rotary valve for maximum efficiency and longevity.

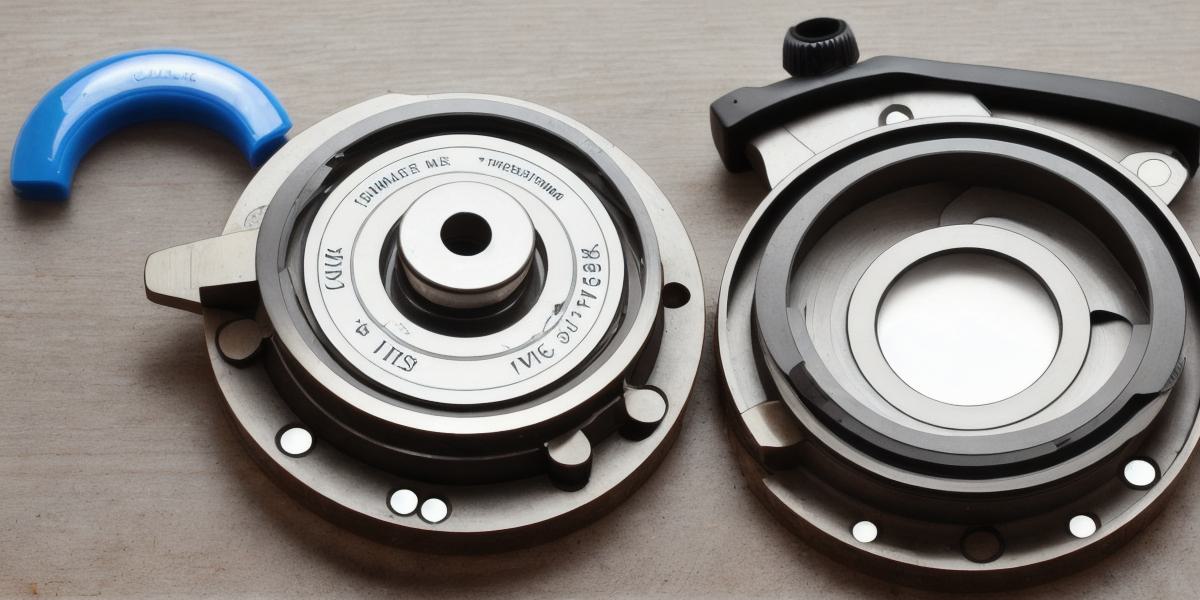

Understanding Your Rotary Valve:

A rotary valve uses a rotating disk to control airflow into the instrument, allowing you to adjust the amount of air entering the tuba and affect its sound quality. The rotary valve consists of several components, including the disk, spool, and stem. These components work together to regulate airflow into the tuba.

Maintenance Tips:

- Clean Regularly: Dirt and debris can accumulate on your rotary valve over time, affecting its performance and damaging the components. Use a soft brush or compressed air to clean your rotary valve regularly. You can also use a cleaning solution specifically designed for brass instruments. It’s essential to clean your rotary valve thoroughly after every playing session, especially if you play in dusty or humid environments.

- Adjust Disk Position: The position of the disk on your rotary valve can affect sound quality. Adjust as needed to achieve the desired sound. You can adjust the disk by turning it clockwise or counterclockwise. A clockwise rotation will reduce the amount of air entering the tuba, while a counterclockwise rotation will increase it.

- Lubricate Components: Regular lubrication with silicone-based lubricant specifically designed for brass instruments helps prevent rusting and other types of damage that can occur when the valve is not properly lubricated. Lubricating the rotary valve will also ensure smooth operation, making it easier to play and control.

- Check for Leaks: If your rotary valve leaks, it can cause damage to the instrument and affect its sound quality. To check, run water through the tuba and listen for any unusual sounds. Tighten connections around the valve stem and disk if necessary. If you notice a severe leak, consider professional repair or replacement of the damaged component.

- Store Properly: Store your rotary valve in a dry and clean location, avoiding moisture or extreme temperatures. Consider using a protective cover or case when transporting to prevent damage. Avoid storing your instrument near direct sunlight or heat sources, as this can cause the brass to expand and contract unevenly, damaging the instrument.

FAQs:

- How often should I clean my rotary valve?

Clean every two to three months, depending on frequency of use and storage environment. Cleaning your rotary valve regularly will prevent dirt and debris from building up, ensuring optimal performance and longevity of your instrument. - Can I lubricate with household oil?

No, use silicone-based lubricant specifically designed for brass instruments. Household oils can corrode the brass components of your rotary valve, causing damage that may be irreparable. Use a high-quality lubricant to ensure smooth operation and prevent rusting. - What should I do if my rotary valve leaks?

Tighten connections around the valve stem and disk, and consider professional repair if necessary. If you notice severe leaking, it may be an indication of a damaged component that requires replacement. Contact a professional technician to diagnose and repair the problem. - Can I adjust the pitch of my tuba using the rotary valve?

No, adjusting the disk position on your rotary valve will only affect sound quality, not pitch. Pitch is determined by the size and shape of the mouthpiece, as well as embouchure technique. Adjusting the rotary valve can cause damage to the instrument if done improperly.

Summary:

Proper maintenance of your Wessex Tubas rotary valve is crucial to ensure optimal performance and longevity of your instrument. Clean regularly, adjust disk position as needed, lubricate components, check for leaks, and store properly. With proper maintenance, you can enjoy maximum efficiency and longevity with your Wessex Tubas instrument. Remember that neglecting the rotary valve’s maintenance may result in irreparable damage to the instrument, reducing its value and playability.