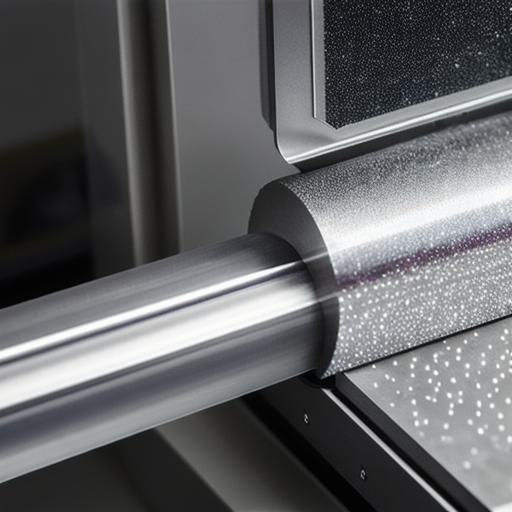

Deburring aluminum is a crucial process for removing sharp edges and burrs from machined surfaces. It is essential for ensuring a smooth, clean finish that enhances the aesthetics and durability of aluminum products. In this guide, we will discuss the best tips, techniques, and tools for deburring aluminum to help you achieve the best results possible.

- Choose the Right Tool

When it comes to deburring aluminum, the choice of tool can make all the difference. There are various types of deburring tools available in the market, including manual tools like files and chisels and automated tools like CNC machines. The right tool for the job will depend on the type of aluminum being deburred, as well as the specific application requirements.

- Select the Right Deburring Technique

There are several techniques you can use to deburr aluminum, including manual deburring, automated deburring, and laser cutting. Each technique has its advantages and disadvantages, and the best choice will depend on your specific needs. For example, manual deburring is ideal for small or simple jobs, while automated deburring is more suitable for larger, more complex projects.

- Use the Right Deburring Medium

The type of debris used in deburring aluminum can have a significant impact on the results achieved. Different types of debris are better suited to different applications and materials. For example, diamond dust is ideal for removing stubborn burrs from aluminum, while sandpaper is suitable for smoothing out surfaces.

- Follow Safety Precautions

Deburring aluminum can be a dangerous process if not done correctly. It is essential to follow safety precautions when working with aluminum, including wearing protective gear like gloves and masks, using appropriate lighting, and avoiding any open flames or sparks.

- Get the Best Results

To get the best results from your deburring process, it is essential to take a few additional steps. These include:

- Using a consistent pressure when applying the deburring medium

- Avoiding overburring, which can damage the aluminum surface and reduce its strength

- Cleaning the workpiece thoroughly before and after deburring

- Inspecting the workpiece closely to ensure that all burrs have been removed

FAQs

- What is the best tool for manual deburring of aluminum?

The best tool for manual deburring of aluminum is a file or chisel specifically designed for aluminum. These tools are available in various sizes and shapes to suit different applications and materials.

- Is automated deburring of aluminum safe?

While automated deburring can be dangerous if not done correctly, it can also be safer than manual deburring if appropriate safety precautions are taken. It is essential to use the right tool, follow proper safety procedures, and monitor the process carefully to avoid any accidents.

- Can diamond dust be used for all types of aluminum?

Diamond dust is an effective debris for removing stubborn burrs from aluminum, but it may not be suitable for all types of aluminum or applications. It is essential to test the debris on a small, inconspicuous area before using it on a larger surface.

Summary

Deburring aluminum is an essential process that requires careful consideration and attention to detail. By choosing the right tool, selecting the right technique, using the right debris, following safety precautions, and getting the best results, you can achieve the smooth, clean finish you desire. Remember to always prioritize safety and take the time to test any new tools or techniques before applying them to your workpiece. With these tips in mind, you’ll be well on your way to producing high-quality aluminum products that meet your customers’ needs and expectations.